- Home

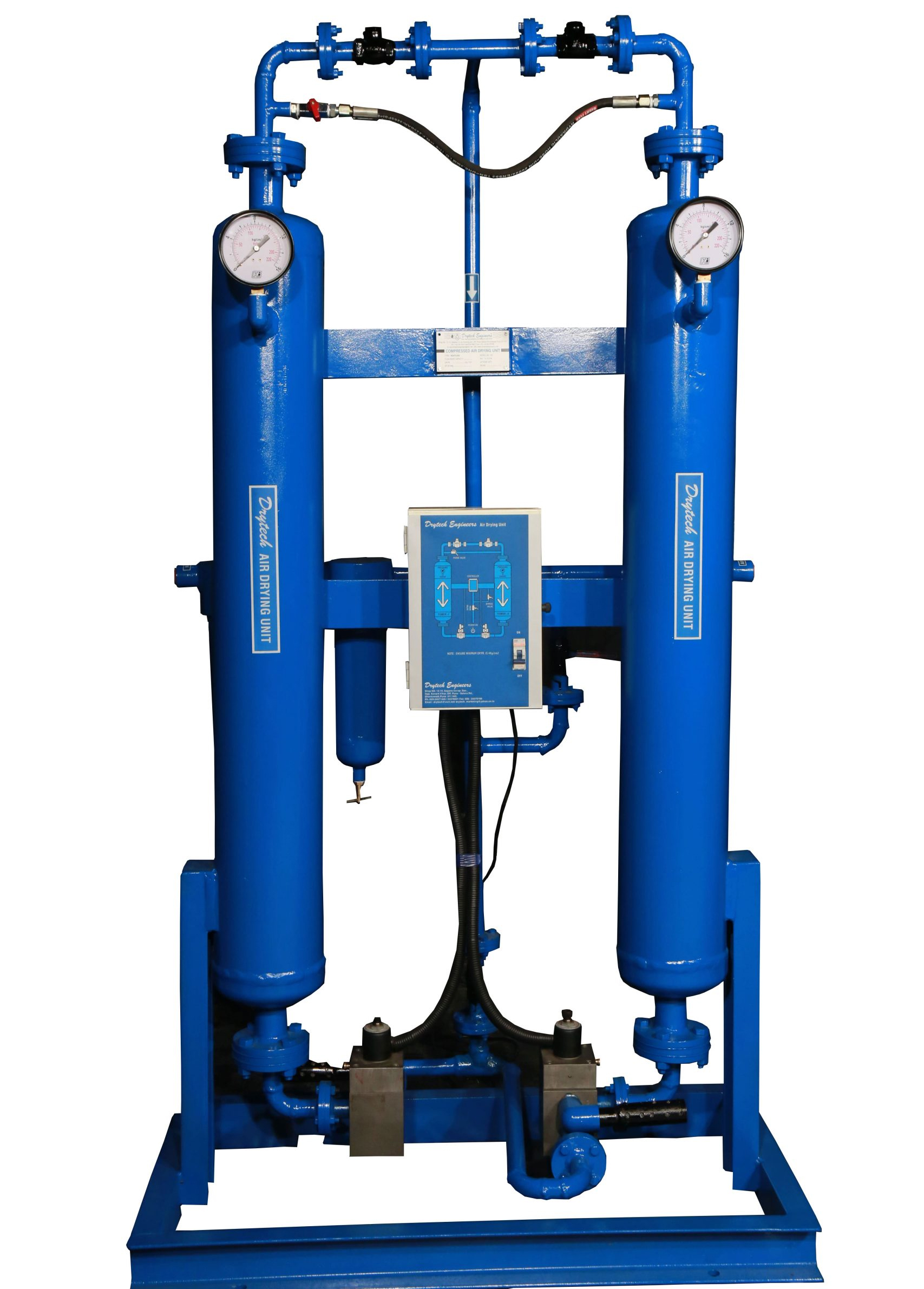

- Heatless Air Dryers

We are Manufacturer, Supplier, Exporter of Heatless Air Dryers, Compressed Air Dryer, Heatless Compressed Air Dryers, Industrial Heatless Compressed Air Dryers, Refrigerated Dryers, Refrigerated Air Dryers and our set up is situated in Pune, Maharashtra, India.

The presence of oil, moisture and dust particles in compressed air is a well known fact for industrial applications. As the technology advanced with induction of sophisticated modern machinery working on compressed air, the usage of recommended quality class of air as per machine manufacturer or International Standard Organisation (ISO)or Pneurope recommendation has become necessary.

The usage of filtered, dry air as per above recommendations results in reduce wear and tear, increased machine uptime, lower rejections, better product quality and above all save in energy / save in time / save in man hours finally resulting to higher business profitability.

Drytech Air Dryer Unit-HD series (Heatless) type offers quality class of air desired as per various recommendations for different pneumatic applications. The stationary air drying unit with negligible maintenance, lesser operating cost and longer service life is the right selection for pneumatically operated machines which needs purified compressed air.

It will be advisable to select dryer in following manner.

- As per ISO 8573.1 for various applications.

- Based on proper flow, pressure and temperature basis for better efficiency.

- Operation

- Salient Features

- Flow Capacity Chart

The complete ADU (Air Dryer Unit) operates in following three modes:

The wet saturated compressed air coming from set of pre filters is led through one of the inlet valve (controlled by electronic timer) to the desiccant bed tower.The highly hygroscopic desiccant bed with sufficient air resident time due to proper velocity results in absorbing the moisture vapour and dries the air to desired level of dew point

The small amount of dried air at almost atmospheric pressure is led through purge line to the saturated desiccant bed tower.The absorbed moisture in desiccant bed at earlier drying mode is desorbed in purged dry air and regeneration takes place.

To avoid the pressure fluctuations at outlet of dryer,the regeneration mode tower is put in for pressurisation before it switches to drying mode.

The entire operation is electronic timer controlled and automatic at various modes shown above for proper sequence and timing.The total cycle time is 10 minutes or as per timer selection for required dew point.

- Operating on ADSORPTION principle; Hence prevents entrainment of moisture in the pipe line however long it may be.

- The most compact skid mounted unit supplied in READY FOR USE state by connecting compressed air at inlet and outlet.

- The stationary working system requires negligible maintenance.

- Assured atmospheric dew point equal to (-) 40 deg.C. or (-) 70 deg.C. as required.

- Ideal purging as per desiccant manufacturers instructions for regeneration.

- Lesser pressure drop in total unit.

- Modified purge silencer causing less noise.

- Designed for Indian as well Global atmospheric condition.

- Easy for installation and commissioning.

| Model | Flow | End Conn. | Conn Type | WT.KGS (appx) | ||

| M3/hr | cfm | |||||

| HD V | 9 | 5 | ½” | BSPT(F) | 25 | |

| HD V1 | 17 | 10 | ½” | BSPT(F) | 35 | |

| HD V2 | 25 | 15 | ½” | BSPT(F) | 70 | |

| HD V3 | 34 | 20 | ½” | BSPT(F) | 88 | |

| HD 001 | 50 | 30 | ½” | BSPT(F) | 105 | |

| HD 001V | 80 | 45 | 3/4″ | BSPT(F) | 150 | |

| HD 002 | 100 | 60 | 3/4″ | BSPT(F) | 180 | |

| HD 002V | 130 | 75 | 3/4″ | BSPT(F) | 190 | |

| HD 003V | 170 | 100 | 1″ | BSPT(F) | 350 | |

| HD 004V | 240 | 140 | 1″ | BSPT(F) | 380 | |

| HD 007 | 340 | 200 | 11/2″ | FLDG.ASA 150# | 430 | |

| HD 009V | 475 | 280 | 11/2″ | FLDG.ASA 150# | 560 | |

| HD 012V | 650 | 380 | 2″ | FLDG.ASA 150# | 670 | |

| HD 016V | 850 | 500 | 3″ | FLDG.ASA 150# | 980 | |

| HD 020V | 1050 | 620 | 3″ | FLDG.ASA 150# | 1250 | |

| HD 025 | 1290 | 760 | 3″ | FLDG.ASA 150# | 1860 | |

| HD 038 | 1940 | 1140 | 4″ | FLDG.ASA 150# | 3850 | |